ALPEWA

Variobend V2.5: sheet metal bending enters the fully electric era

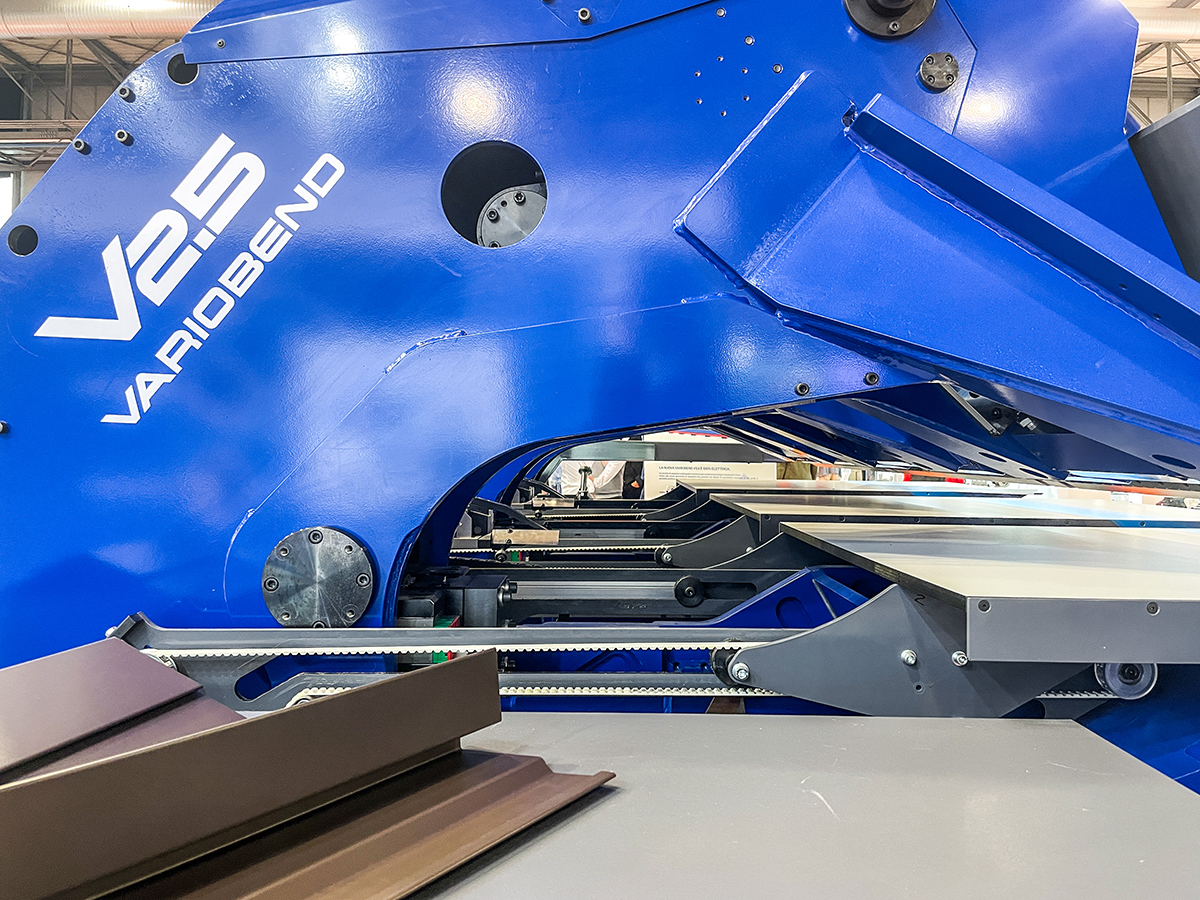

In the world of sheet metal working, innovation increasingly speaks the language of efficiency, precision and sustainability. The new Variobend V2.5, a 100% electric double-bending machine, represents a real revolution in the sector.

Thanks to the full electric E-Drive technology, the V2.5 eliminates hydraulic systems, reduces energy consumption and guarantees high performance with minimal environmental impact. Its 300° bending geometry allows for complex machining, opening up new possibilities in the design of profiles with aspect ratios up to 2:1.

The digital heart of the machine is the Variobend V-Touch software, which allows for quick, intuitive and customisable management via a 21.5’ HD screen. Advanced functions such as bend simulation, conical bending and automatic profile nesting further improve the user experience.

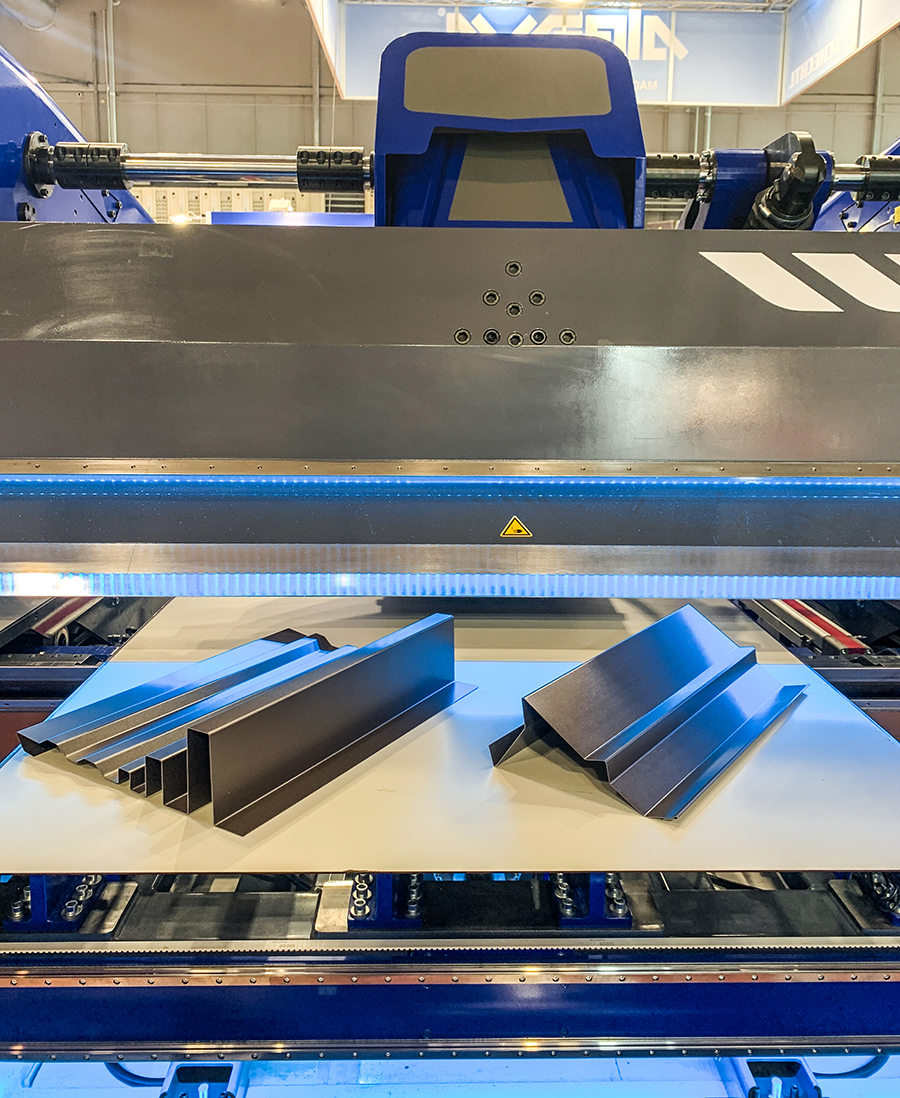

Structurally, the V2.5 guarantees rigidity and millimetric precision, thanks to a high-strength frame and Hardox steel components that prevent deformation and unwanted marks. The automatic cutter independently adjusts the cutting distance and overlap according to the material, optimising results and reducing manual intervention.

The DPR (Dynamic Pressure Regulation) system intelligently manages the closing pressure on each upright, while the conical depth stop allows for easy assembly of multi-part profiles with wide tolerance (+/-120 mm over 6 metres). Finally, the automatic clamps speed up production, allowing more profiles to be processed with a single operator.

Designed with safety and ergonomics in mind, the V2.5 offers protective fencing, an advanced remote control, a mobile console and customised paintwork on request.

With Variobend V2.5, sheet metal bending enters a new era, where efficiency, versatility and sustainability become the standard.

![]()

![]()

![]()