OMERA

New technology and energy saving solutions

On the occasion of LAMIERA 2025, OMERA will present, as a national preview, the innovative hydraulic press designed for energy saving and recovery.

On the occasion of LAMIERA 2025, OMERA will present, as a national preview, the innovative hydraulic press designed for energy saving and recovery.

It consists in the implementation of the ENERGY RECOVERY and ENERGY SAVING packages on an 80-ton hydraulic C-frame press model OPI.C 80.

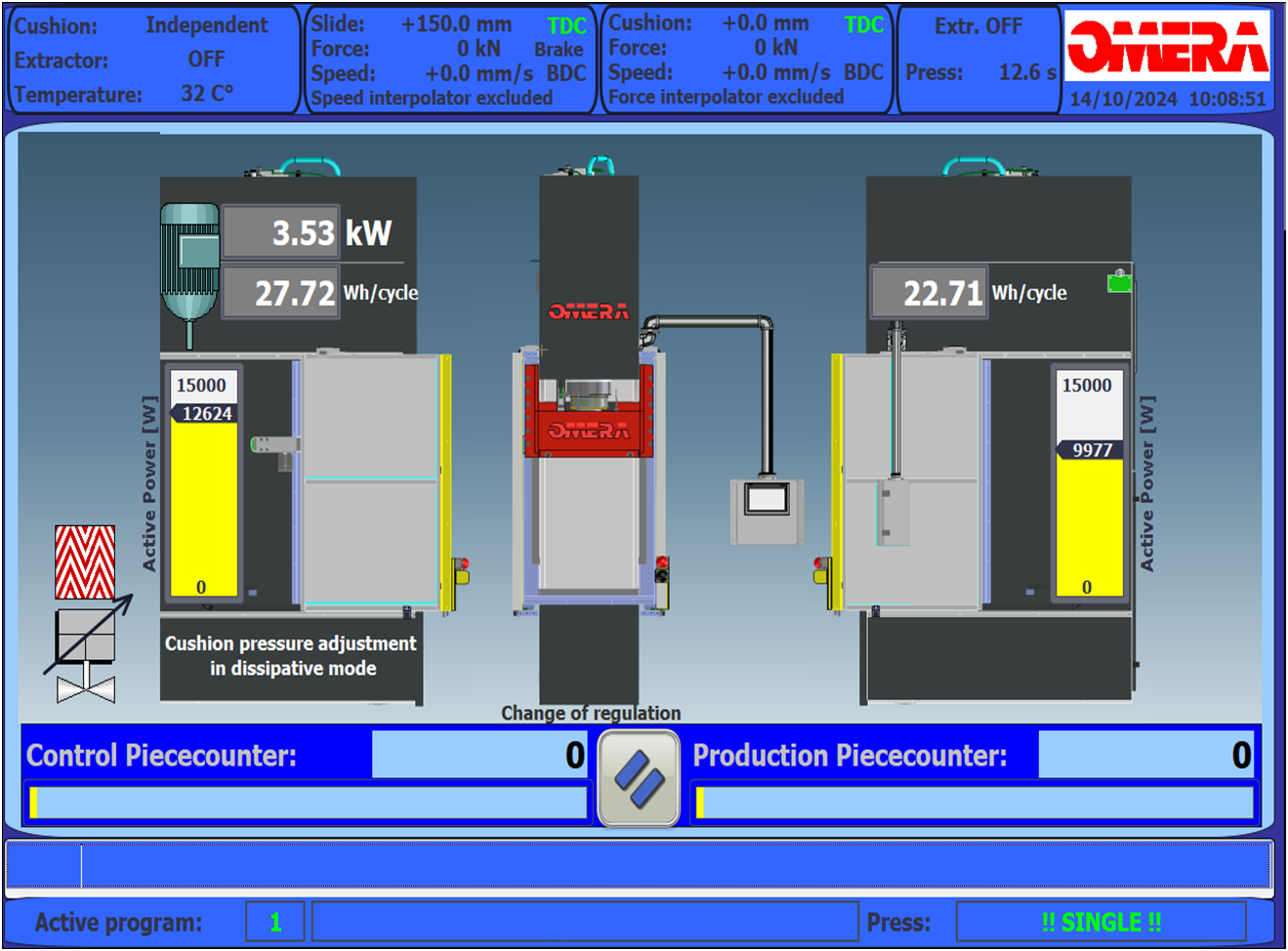

In the last years, customers have been looking for solutions to contain production costs by reducing those attributed to electricity consumption. Here is therefore the ENERGY RECOVERY solution, which, applied to the OPI.C 80 press, consists of an independent motor-pump unit complete with servomotor and high dynamic fixed displacement pump to manage the blank holder. In fact, in a traditional hydraulic press for deep-drawing, the energy dissipated by the blank holder cushion is totally converted into heat and represents the largest share of dissipated energy of the machine. This OMERA solution allows for a net recovery of more than 90% of the energy dissipated by the cushion, which would otherwise be wasted. Another advantage of this system is that it contributes to reducing the needs related to the machine’s cooling system.

The ENERGY SAVING package, thanks to the application of brushless motors or a pump management system with inverter, integrates the following functions:

Motor Start-Stop, during the loading/unloading cycle phases, allowing for energy saving when the machine is not working.

Soft-Start, for a soft start/stop of the motor, obtaining a reduction of current overloads on the company electricity network. The customer can immediately check the amount of power consumed thanks to the electrical power measurement and monitoring system integrated into the machine’s electrical cabinet. This system also allows the monitoring and precise analysis of energy consumption through a dedicated software page on the operator panel.

![]()

![]()

![]()