HOMBERGER

Manual/Automatic Laser Welding Cell with Cobot Assistance

![]() In today’s industrial landscape, laser welding is a true evolution compared to traditional methods (MIG, TIG, Plasma), offering greater precision, speed, and cleanliness. In collaboration with Lastek and Bai Automazione, Homberger has developed a compact and innovative collaborative laser welding cell, combining robotic efficiency with the versatility of manual work.

In today’s industrial landscape, laser welding is a true evolution compared to traditional methods (MIG, TIG, Plasma), offering greater precision, speed, and cleanliness. In collaboration with Lastek and Bai Automazione, Homberger has developed a compact and innovative collaborative laser welding cell, combining robotic efficiency with the versatility of manual work.

The new cell will be unveiled for the first time at the fair and features a Plug & Play system, equipped with a Doosan Robotics cobot and a high-precision Fanuci laser system. At the heart of the solution lies a hybrid approach, allowing operators to easily switch from automatic to manual mode thanks to a quick-release laser head mechanism. This enables complex joints to be tackled with ease while maintaining repeatability for standard operations.

The cell includes safety light indicators, protective glass, an advanced fume extraction system, and a smart lock to ensure maximum safety. Its compact design allows for easy integration even in tight spaces, making it ideal for workshops or production departments aiming for Industry 4.0 transition.

The benefits are tangible: higher quality, less waste, faster programming, and accelerated ROI. It’s a solution that enables companies to work with small or customized batches, with strong relevance in the automotive, plant engineering, metal fabrication, and light mechanical sectors.

LAMIERA 2025 will be the opportunity to see the cell live in action at Hall 15 – Booth E30, and to talk directly with Homberger’s experts about the future of industrial welding.

![]()

![]()

Professional Sheet Metal Processing Tools

Homberger will showcase a selection of top brands for metalworking, offering concrete and efficient solutions to industry professionals. Among the stand highlights: Trumpf, N.KO, Gerima, Jepson Power, Eisenblätter, HMT, and Profit—a perfect blend of technological innovation, quality, and reliability.

Big news at the fair: Homberger will present the new Trumpf TruTool TSC 200, a compact and powerful machine for cleaning slats in laser cutting systems. Designed to remove slag on fiber lasers (from 6 kW) and suitable for hard materials up to 25 mm thick, it’s a robust and high-performing solution to maintain high system efficiency. It will complement the best-selling and most reliable grid cleaner on the market, the Trumpf TruTool TSC 100, as well as the PS 100 part separator—providing an even more complete offer tailored to the needs of laser professionals.

Also featured will be Trumpf’s portable beveling and deburring machines, long synonymous with precision and reliability. Beveling with a punch, in particular, offers a unique alternative to traditional beveling, providing top safety and performance: up to 15 mm bevels on steel in a single pass.

With Gerima and N.KO, Homberger will offer a full range of portable and stationary beveling machines. N.KO Machines stand out for their excellent value and comprehensive range, while Gerima’s German-made tools are prized for their quality, durability, and reliability—hallmarks of a market leader.

Live demos at the booth will include:

- Cutting and edge preparation

- Beveling and chamfering

Compact yet powerful machines, designed to deliver consistent performance, ease of use, and maximum safety—ideal solutions for workshops, metal fabricators, and high-volume production environments.

Discover more about Homberger’s Professional Tools for beveling and deburring.

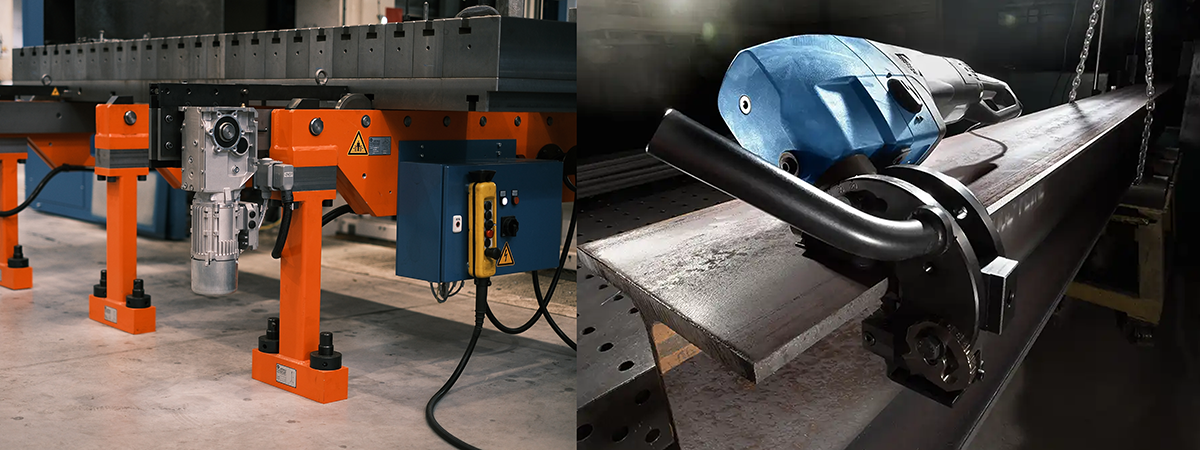

Die Change: Safe and Efficient Handling Solutions

At the heart of Homberger’s offering at LAMIERA 2025 is also a selection of advanced solutions for die handling and changeover, developed by German partner Güthle Pressenspannen, a European leader in the design of quick die setup systems for production environments.

At Hall 15 – Booth E04, Homberger will present:

- Die change carts: stable, easy to maneuver, and configurable for different die sizes

- Motorized shelves: ideal for supporting heavy loads and facilitating die entry into presses

- Positioning bars and modular inserts: designed to minimize setup time and enhance precision

These solutions are built to deliver more efficiency, improved safety, and reduced downtime in production departments where flexibility is key. Thanks to a combination of mechanical handling, intelligent automation, and high-quality components, Homberger and Güthle provide practical tools to optimize workflow and ensure operational continuity.

During the event, the technical team will be available for personalized consultations and to guide visitors in selecting the solution best suited to their production needs.

![]()

![]()