FICEP

Gemini Laser: the future of laser cutting

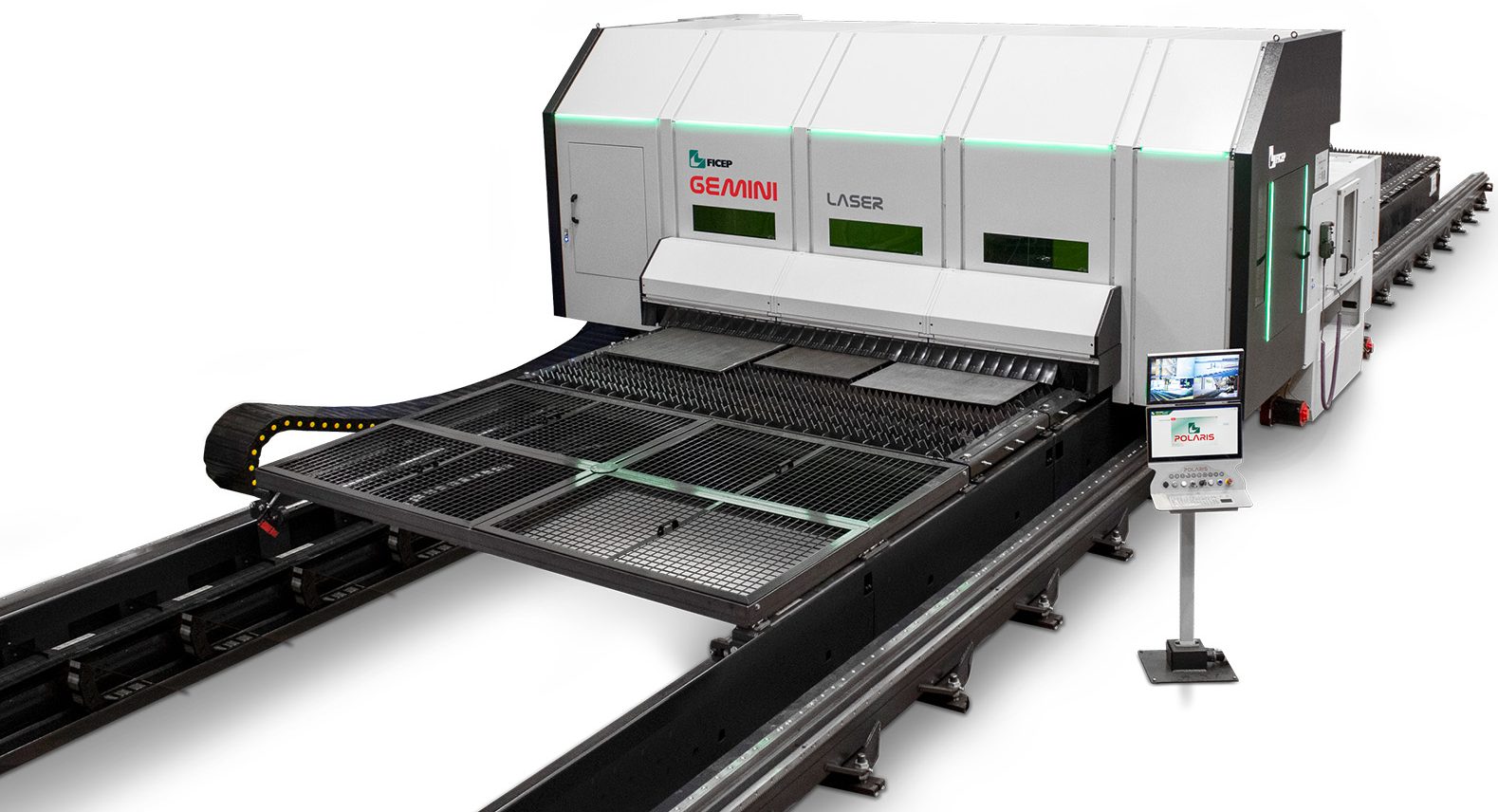

The evolution of high-power laser systems and cost reductions have transformed the structural steel industry, making the integration of laser cutting with mechanical processing essential. FICEP responds with GEMINI LASER, a solution that merges laser technology with the outstanding performance of the renowned GEMINI range. GEMINI LASER is an automatic gantry CNC system designed for drilling, milling, tapping, marking, and beveling, now enhanced with a laser source ranging from 12 to 30 kW (or higher for specific applications), capable of cutting plates from 5 to 60 mm thick. The system delivers high-quality cutting, reducing kerf width and waste, while allowing for complex bevel cutting at ±45° for V, Y, X, and K cuts. Safety is ensured by a mobile protective enclosure that contains the laser beams, supported by an exhaust system that removes gases, while the automatic nozzle optimizes performance and tool longevity. Additionally, GEMINI LASER features high-speed drilling and milling capabilities (with a spindle reaching up to 7,000 RPM) and an automatic tool changer (holding up to 24 tools) to minimize downtime. Its compact dual-beam structure minimizes deflection, ensuring superior stability, while smart clamping and referencing systems reduce setup times, optimize nesting, and limit waste. This solution can be integrated with an automatic unloading system (either a 4/6-axis robotic arm or a cartesian system) that handles component removal and storage, ensuring continuous production flow. The Steel Projects software manages the entire production process, from design to fabrication, enhancing communication, monitoring, and planning while reducing lead times and material waste.

The evolution of high-power laser systems and cost reductions have transformed the structural steel industry, making the integration of laser cutting with mechanical processing essential. FICEP responds with GEMINI LASER, a solution that merges laser technology with the outstanding performance of the renowned GEMINI range. GEMINI LASER is an automatic gantry CNC system designed for drilling, milling, tapping, marking, and beveling, now enhanced with a laser source ranging from 12 to 30 kW (or higher for specific applications), capable of cutting plates from 5 to 60 mm thick. The system delivers high-quality cutting, reducing kerf width and waste, while allowing for complex bevel cutting at ±45° for V, Y, X, and K cuts. Safety is ensured by a mobile protective enclosure that contains the laser beams, supported by an exhaust system that removes gases, while the automatic nozzle optimizes performance and tool longevity. Additionally, GEMINI LASER features high-speed drilling and milling capabilities (with a spindle reaching up to 7,000 RPM) and an automatic tool changer (holding up to 24 tools) to minimize downtime. Its compact dual-beam structure minimizes deflection, ensuring superior stability, while smart clamping and referencing systems reduce setup times, optimize nesting, and limit waste. This solution can be integrated with an automatic unloading system (either a 4/6-axis robotic arm or a cartesian system) that handles component removal and storage, ensuring continuous production flow. The Steel Projects software manages the entire production process, from design to fabrication, enhancing communication, monitoring, and planning while reducing lead times and material waste.

GEMINI LASER represents a fully integrated solution for laser cutting, drilling, and milling, increasing competitiveness and operational efficiency. With this innovation, FICEP reaffirms its leadership in steel processing technologies, opening new frontiers in industrial fabrication.

![]()

![]()

![]()