OMP

Experts in tube and metal processing, presents the tf220 3d tube laser

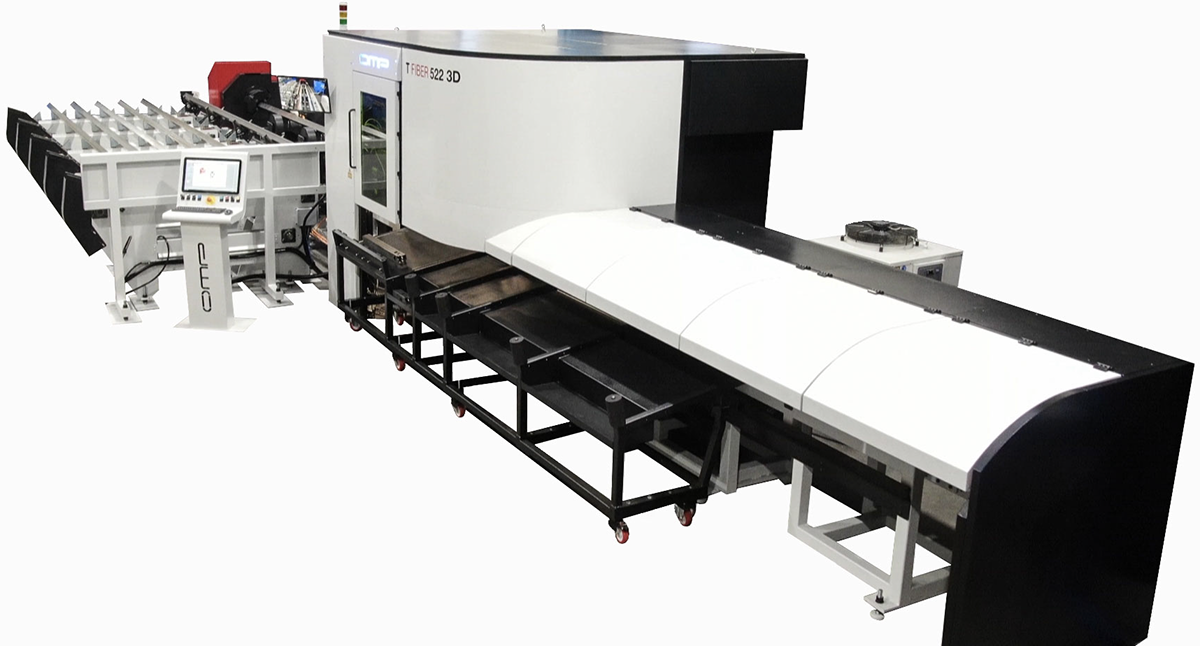

The TF220 laser tube cutting system is an advanced solution designed for precise and fast cutting of metal tubes of various sizes and thicknesses. Thanks to state-of-the-art laser technology and integrated software, this system ensures high productivity and maximum cutting quality. It is equipped with a fiber laser source, capable of processing tubes from Ø20mm up to Ø220mm, as well as open and/or closed profile derivatives.

The TF220 laser tube cutting system is an advanced solution designed for precise and fast cutting of metal tubes of various sizes and thicknesses. Thanks to state-of-the-art laser technology and integrated software, this system ensures high productivity and maximum cutting quality. It is equipped with a fiber laser source, capable of processing tubes from Ø20mm up to Ø220mm, as well as open and/or closed profile derivatives.

The TF220 laser tube, designed and manufactured in Italy, offers excellent versatility in processing tubes and profiles made from a wide range of materials and thicknesses.

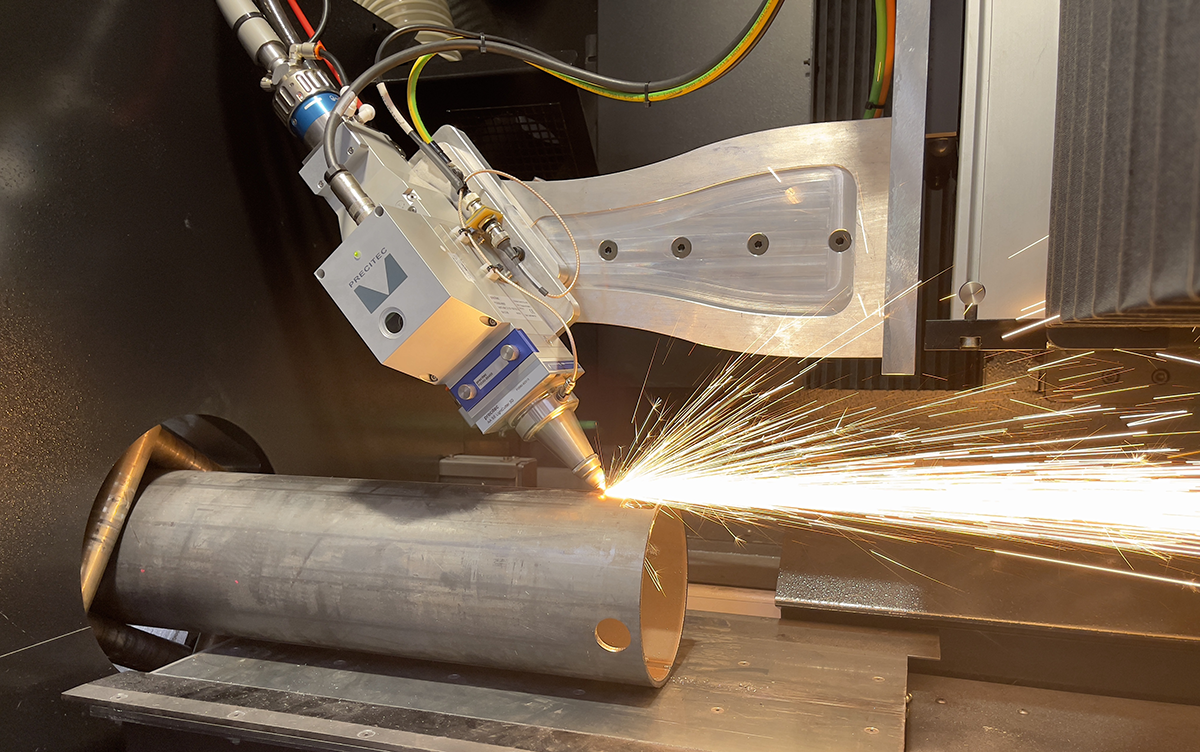

In addition to straight cuts, it performs holes and slots, markings and engravings, male-female joints, chamfers, bevels, and countersinks on round, square, and rectangular tube sections, special boxed profiles, elliptical shapes, and open profiles such as UPN, IPE beams, and angle bars. It is suitable for materials including carbon steel, stainless steel, aluminum alloys, and highly reflective materials.

Using an advanced tracking and control system, the laser head can maintain a constant distance from the tube and adapt to curves, angles, and other complex shapes. All programming phases are managed by Almacam Tube, a CAD-CAM software for tube and profile cutting.

This system combines working power with high cutting quality even on thick materials. Its high speed and maximum precision, achieved through linear drive technology, maximize the machine’s potential.

With the CM-CP magazine loader, you can work autonomously, produce from bundles, or load one or a few bars at a time. Automatic roller unloading allows for the discharge of both short and long pieces while separating scrap materials.

From weld seam readers to remote cameras and customizable loading and unloading options, we offer tailored solutions to maximize your productivity.

![]()

![]()

![]()