ALMA

From complexity to efficiency: Almacam’s impact on sheet metal companies

Almacam software suite addresses the challenges faced by sheet metal companies, offering powerful CAD/CAM capabilities, including the world’s most advanced nesting technology.

Almacam software suite addresses the challenges faced by sheet metal companies, offering powerful CAD/CAM capabilities, including the world’s most advanced nesting technology.

Subcontractors using Almacam enjoy its user-friendly interface and intuitive workflow, enabling them to program 2D and 3D machines and robots of all brands.

Focus on 4 key modules of Almacam

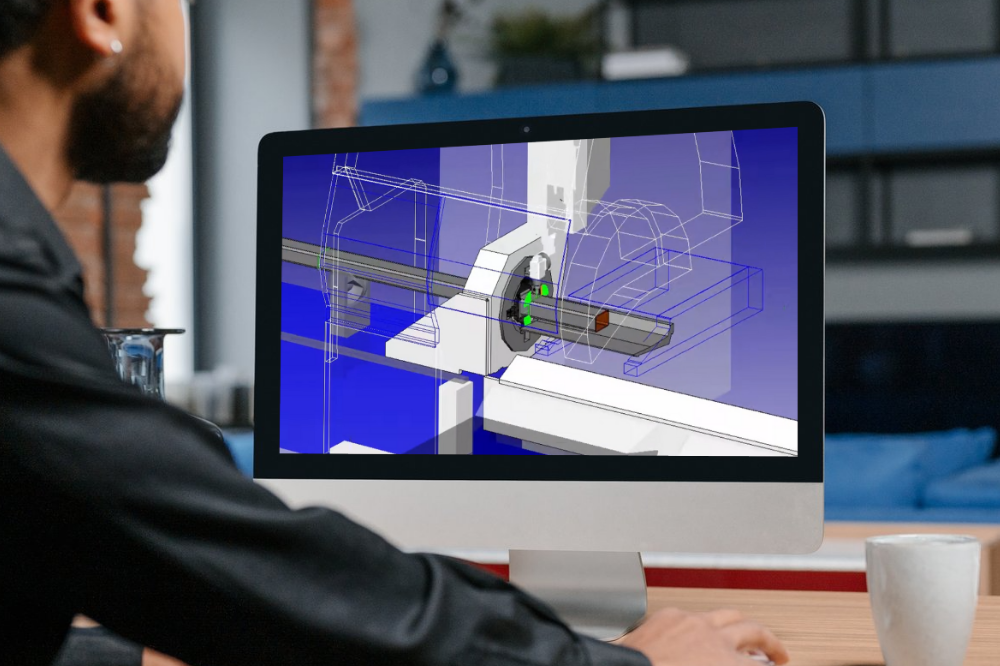

Almacam Tube: Improve production efficiency with the most advanced automated tube cutting solution

- Manage all tube cutting machines whatever the brands, the kinematics, and the number of driven axes.

- Achieve exceptional cutting precision, delivering perfectly clean parts

- Automation in cutting preparation saves time and improves part quality: optimized cutting trajectories, sequences.

Almaquote: make quotation for sheet metals parts easier and faster

- Generate highly accurate quotes that reflect real workshop conditions with a comprehensive quoting tool designed specifically for sheet metal businesses.

- Seamlessly manage the entire quoting process, from importing 2D/3D parts to nesting and sending quotes, while considering part geometry and preparation times.

Assembly2cam, analyze assemblies with intelligent recognition

- Effortlessly import a CAD assembly and let Assembly2cam do the work for you. With powerful geometric recognition algorithms, it automatically identifies each part of the assembly, its properties, and quantities.

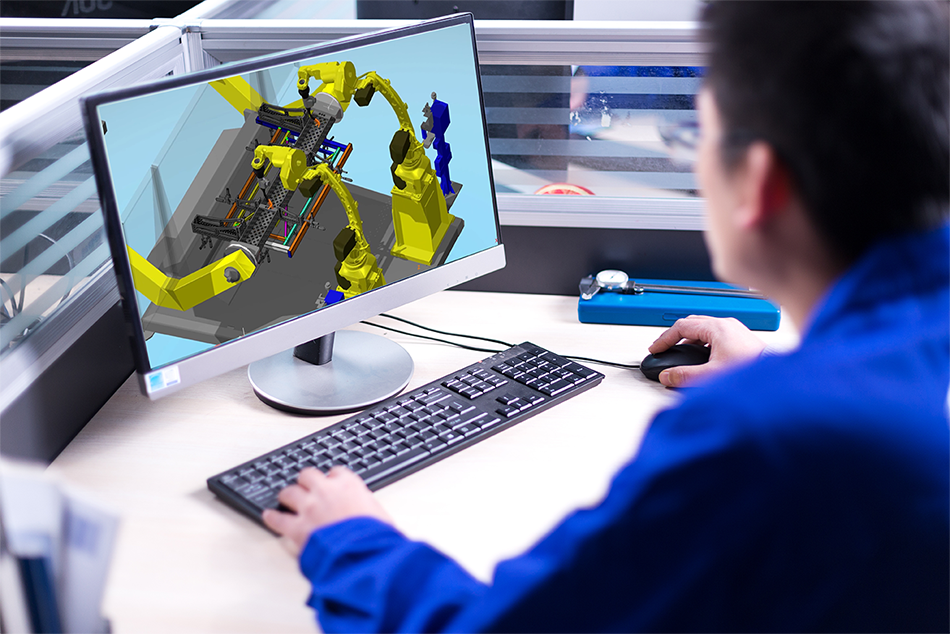

Almacam Weld, the Smart Automated OLP Software to Master Complex Robotic Welding

- Everything is weldable with robotics, even small series and complex assemblies.

- Offline Programming replaces time-consuming manual setup, enabling faster adjustments.

- Simulating welding processes reduces errors, ensuring precision and better quality.

- Almacam Weld cuts costs by allowing virtual program testing without halting production.

![]()

![]()

![]()