BLM GROUP

The new LS7 at LAMIERA trade show

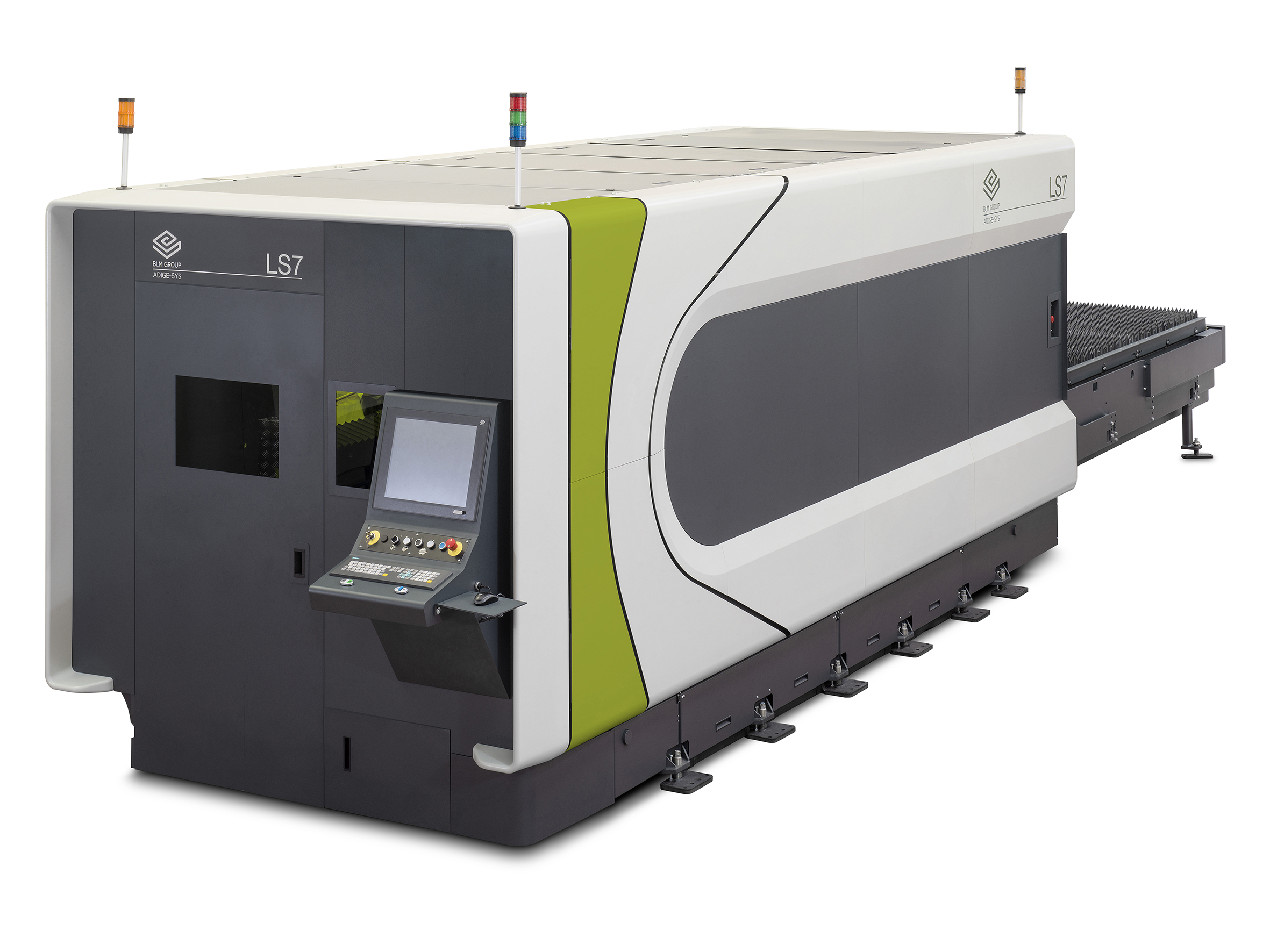

BLM GROUP is presenting the latest version of its LS7 sheet metal laser cutting machine combined with an automatic loading and unloading system. The system has been upgraded to increase its power capacity to a 20-kW laser source, while maintaining its original features: high-quality cutting, ease of use and ultra-fast pallet change. LS7 allows a wide range of metals, including stainless steel, iron, aluminum or copper, to be processed with high and consistent quality. The laser machine integrates into the production process with all the advantages of fiber lasers: low energy consumption, low maintenance and cutting of highly reflective materials.

BLM GROUP is presenting the latest version of its LS7 sheet metal laser cutting machine combined with an automatic loading and unloading system. The system has been upgraded to increase its power capacity to a 20-kW laser source, while maintaining its original features: high-quality cutting, ease of use and ultra-fast pallet change. LS7 allows a wide range of metals, including stainless steel, iron, aluminum or copper, to be processed with high and consistent quality. The laser machine integrates into the production process with all the advantages of fiber lasers: low energy consumption, low maintenance and cutting of highly reflective materials.

Cutting quality and ease of use

The laser cutting head automatically adapts internal optics to material thickness, and head edge sensors monitor working conditions to ensure clean and accurate cutting. Whether cutting in nitrogen, oxygen, gas mixer, or compressed air, it is easy to set up the machine and go into production.

Automation: the key to increasing productivity

The Sheet Metal Fair will also feature an automatic sheet metal loading and unloading system. A solution designed to simplify the operator’s work and increase plant productivity. This type of automation is equipped with an automatic system for sheet metal peeling and thickness control, which ensures the correct detachment of the raw material, and scratch-resistant belts to preserve the quality of the material. The compact system feeds the laser machine with new sheets and picks up the processed sheets automatically. It can be combined with a single tower that can be retrofitted after the initial installation.

Alternatively, the machine can be equipped with a compact tower for material feeding and storage. The compact tower has an innovative feature of free access to the pallet changer. The loading pallet can be lifted to allow the operator to feed the laser machine pallet directly in the event of urgent batches or material out of specification.

![]()

![]()

![]()